March 2000

Fulton, IL, USA - The masonry work - The "fieldwall"

The Dutch are back in Fulton again, and this time there's masons.

During the weekend of March 25/26 Messrs. Wijndelt Drent and Johan Havenga arrived in Fulton to start the masonry work. Project manager Bert Bulder joined them during their first week. The masonry part of the project is expected to be ready towards the end of April 2000.

Before starting their own work though, the masons first went and checked on the work that was done by Lawrence & Son, Contractors during winter time.

They soon found out that Lawrence did a fine job; finishing the belt, installing a railing on top of the belt, constructing the concrete facade, walk ways and the office space between the entrance and the "onderbouw" ( the lower part of the windmill) while others were installing all the necessary utilities like electricity, water, air and telephone.

After locally purchasing the necessary ingredients for their mortar, Johan and Wijni (short for Wijndelt) were ready to start their work by Tuesday afternoon.

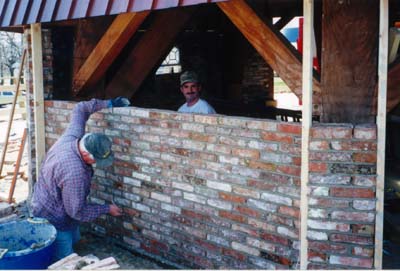

Brickwork is planned for the concrete facade and the "fieldwall" on top of the belt.. The mason's planning called for erecting this "fieldwall", covering the lower part of the octagon, first.

The historic brick Wijni Drent is using here was shipped from the Netherlands to Fulton in the fall of 1999. The brick came from one single building in the Groningen city of Bedum and date back to about 150 years ago. The authentic, historic brick will really set off the windmill by adding an atmosphere of longevity.

Installing these century old bricks is a work of expertise, and thanks to his almost 40 years of experience Wijni is the person to do this specialist's job.

One can safely state that, although all of the brick come from one single building, no single brick from the 8 pallets that will be used in the fieldwall is exactly alike. They differ in width, height, depth and color, and while some of them are flat, most are not.

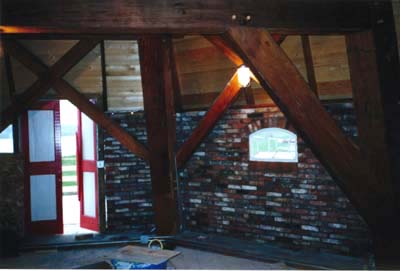

Although an appearance of unevenness might be thought to add to the general look of authenticity, the mason's task is to create a "perfectly even" wall on the outside. The differences in shape and color as such are enough to create the "historic unevenness". The brick have to be installed perfectly level in their horizontal direction and perfectly tilted inwards in their vertical direction. It's only on the inside that the differences in depth of the brick clearly show.

Two crooked nails and a piece of rope create one of the mason's indispensible tools...

Trowels, a brick hammer or a modern-day brick saw are used to create halves, quarters or,

when required, odd-sized brick parts.

A pointing trowel is used to finish the joints.

Of course pointing is done on both sides of the "fieldwall" since both sides will be visible.

A small hand broom is used to create the final looks.

By the end of the week half of the work on the field wall was finished...

thus already giving a good idea of the final looks on both outside and inside.

![]() Hippo

WebDesign Last update: April 7,

2003

Hippo

WebDesign Last update: April 7,

2003

Building windmill De Immigrant

The photos - The complete diary